hammer crusher rotor specification

SANDVIK 700 RANGE HORIZONTAL SHAFT IMPACTORS

2019.3.13 TECHNICAL SPECIFICATION. GETS THE JOB DONE - BOTH OF THEM. The all-new 700 range of Horizontal Shaft impact crushers ofers new levels of safety and eficiency. Developed to comply with new EU legislation, you can configure these smart,

Read More

double-shaft hammer crushers - ThyssenKrupp

2022.11.21 Mobile double-shaft hammer crusher installation on hydraulic walking mechanism at Riyadh Cement Company, Muzahimiyan, Saudi Arabia Type ® TITAN 80D160 Throughput rate 1,300 t/h Semi-mobile double-shaft hammer crusher installation at HeidelbergCement AG, Burglengenfeld, Germany Type TITAN ® 80D160 Throughput

Read More

Nordberg® NP Series™ Horizontal shaft impact (HSI)

2023.7.20 Nordberg® NP Series™ HSI crushers technical specifications Model Crushing range Rotor weight* Rotor diameter Rotor width Nordberg® NP1415™ Primary 7 880 kg 1 370 mm 1 500 mm Nordberg® NP1620™ Primary 15 020 kg 1 610 mm 2 005 mm Nordberg® NP13™ Secondary and tertiary 4 575 kg 1 205 mm 1 285 mm

Read More

crusher

2022.6.27 crusher’s two jaws; one is fixed while the other reciprocates. ... Rotor Diameter mm 1100 1100 1300 1500 1600 inch 43 43 51.2 59 63 Rotor Width mm 1070 1400 1300 1500 2000 ... Hammer crushers are employed for the fine crushing of medium-hard to soft materials. Due to their high level of flexibility, hammer crushers can be adapted to

Read More

HAZEMAG Hammer Crusher HDS - Siming

2017.5.12 Rotor. The rotor body together with shaft and bearings forms the »heart« of the impact crusher. Each rotor comprises a central shaft onto which discs are affixed. Between the discs, free-swinging hammers are mounted on hammer bolts extending over the full width of the crusher and secured at both ends to the outer discs.

Read More

European-Type Hammer Crusher

2020.4.11 The European-type Hammer Crusher is of high capacity, high crushing ratio, simple structure, uniform output granularity as well as low electricity consumption, and is easy to maintain and operate. The moisture of the raw material should be less than 10% - 15% to avoid the blocking of material during the crushing process.

Read More

Secondary Impact Crusher HSI - HAZEMAG

PRODUCT DESCRIPTION. 🡩 TECHNICAL DATA. INDUSTRY. ROTOR. HOUSING SYSTEM. IMPACT APRONS. GRINDING PATH. HAZTRONIC. FORMER PRODUCT LINE. HAZEMAG redefines secondary crushing

Read More

Hammer mill HUM - HAZEMAG

Rotor(s) The HAZEMAG HUM Hammermill is equipped with one reversible rotor. The heavy-duty rotor employed in HAZEMAG’s Hammermills is of a steel disc design, with free swinging (360°) hammers mounted between the discs. The rotor is shaft mounted and fitted with self-aligning roller bearings. The rotor bearings are equipped with temperature ...

Read More

MEKA Crushing Screening and Concrete Batching

2022.6.27 MEKA Crushing Screening and Concrete Batching Technologies

Read More

Impact hammer crusher capacity and specification

2024.4.2 An impact hammer crusher is a type of crusher that uses hammers to break rocks and stones into smaller pieces. The hammers are attached to a rotor that spins at high speed. The rocks or stones are fed into the crusher, and the hammers hit them, breaking them into smaller pieces.

Read More

Nordberg® NP Series™ Horizontal shaft impact (HSI)

2023.7.20 the crusher and the whole plant, allowing the operator ... hammer and the breaker plate. This operator´s pre- ... Nordberg® NP Series™ HSI crushers technical specifications Model Crushing range Rotor weight* Rotor diameter Rotor width Nordberg® NP1415™ Primary 7 880 kg 1 370 mm 1 500 mm

Read More

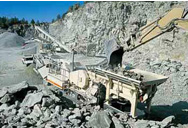

RM 100GO! - RUBBLE MASTER - Mobile Crushers

4 天之前 The RM 100GO! is the powerful high performance mobile crusher among the mobile crushers, exceeding all your expectations. Weighing in at only 29 t when empty this is a particularly high-capacity machine which

Read More

Hammer Crusher Rotor Specifications – stone cruxder

The rotor is the heart of the hammer crusher, onto which hammers are mounted. It rotates at high speeds, propelling the hammers against the materials, breaking them down into smaller particles. The rotor’s design and specifications directly impact the crusher’s crushing power and the consistency of the particle size distribution.

Read More

Hammer Crushers - HAZEMAG

Our Hammer Crushers. HAZEMAG offers a double rotor Hammer Crusher and is used as primary crusher in cement industry for soft to medium-hard rock. They offer a very high crushing ration of 10:1 up to 80:1. The product is ideal as feed material to downstream ball mills or vertical roller mills. Double rotor Hammer Crushers are able to process ...

Read More

Hammer Crusher Machine - Big Crushing Ratio And High

Rotor specification(mm) Feeding size(mm) Output size(mm) Capacity(t/h) for crushing limestone: Motor power(kw) FHC-20: Φ800×400 <100: Average<3: 20: 30-37: FHC-30: Φ800×600 ... Hammer crusher mainly depends on the impact to break the materials. The crushing process is as follows: The material fed into the hammer mill crusher is first ...

Read More

Reversible Hammer Mill Crusher Williams Patent Crusher®

Call (314) 621-3348, email us at info@williamscrusher or locate an agent near you. The Williams Reversible Hammer Mill reduces service hours with its ability to reverse the rotor and add new life to the hammers. Call our sales engineers today to learn more.

Read More

Hammer Concrete Crushers Specifications Datasheets - LECTURA Specs

670 mm. More. FK55. Hammer. 5.9 t. 1350 mm. More. See detailed specifications and technical data for Concrete Crushers. Get more in-depth insight on Hammer Concrete Crushers and find specific machine specifications on LECTURA Specs.

Read More

Crusher Rotor - Hammer Mill Rotor Design and

High crushing efficiency: The crusher rotor adopts advanced design and manufacturing technology, and has good dynamic characteristics and crushing efficiency. Its high-speed rotation and unique structural design can quickly crush various materials and improve production efficiency. High wear resistance: Crusher rotors are usually made of high ...

Read More

Hammer Mill Crusher Grinder - 911 Metallurgist

2016.2.25 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and

Read More

Cement Crusher Crushers for Cement Plant AGICO Cement

The hammer crusher is a kind of crushing machine which uses impact energy to crush materials. It is mainly composed of shell, rotor, impact iron, lining plate, and screening strips. The shell is divided into upper and lower parts, which are welded after being cut by the steel plate. There is a high manganese steel lining plate inside the shell ...

Read More

Rotor - Stone Crusher Spare Parts, Crusher

2023.6.2 As for the weak part by stress analysis nephogram of rotor, we take the way of reinforcement and use the high-strength steel, and also the protective design with armor-style, which can increase 50%-100%

Read More

A Comprehensive Guide to Different Types of

2023.2.15 Hammer crusher wear parts are primarily composed of the hammer, rotor, and liner plates. The hammer is the main working component of the hammer crusher, and it needs to be made from high-quality

Read More

TECHNICAL SPECIFICATIONS SANDVIK QJ341+ JAW

2021.4.7 JAW CRUSHER TECHNICAL SPECIFICATIONS QJ341+ DATA Crusher Type Single toggle C12 jaw crusher Feed opening 1.20 m x 750 mm / 47” x 29” Speed 264 - 283 rpm Adjustment type Hydraulic wedge CSS range 50 - 160 mm / 2” - 6” QJ341+ DATA Power pack Engine CAT C9.3B Stage 5 / T4F 280 kW / 375 hp CAT C9 T3 261 kW / 350 hp

Read More

Cement Crusher Crushers for Cement Plant AGICO Cement

It is mainly composed of shell, rotor, impact iron, lining plate, and screening strips. The shell is divided into upper and lower parts, which are welded after being cut by the steel plate. ... AGICO Hammer Crusher Specifications. Name Model SPC Parameters Capacity (t/h) Motor power(KW) Weight (t) Size; Hammer crusher: AGPC-64: φ600ⅹ400 ...

Read More

Hammer Crusher Machine Hammer Crusher Cement Crusher

Cement hammer crusher machine is made up of box, rotor, hammer, impact plate, sieve plate and other parts. The main working part of hammer cement crusher is a rotor with a hammer, also known as hammer head. The material is beaten, impacted, sheared and grinded by the hammer moving at high velocity. At the bottom of rotor, there is a screener ...

Read More

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT

2020.4.14 ROTOR with all necessary standard wear parts fitted. One complete spare rotor with standard wear parts and tip plates. Non standard wear parts are available for abrasive material. FRAME ARRANGEMENT Crusher support frame with anti-vibration dampers and transportation legs. Motor Mounting Bracket with hydraulic (belt tensioning)

Read More

McLanahan Hammermill Crushers

In the case of the HammerMaster and LimeMaster crushers, McLanahan has designed the crusher with rotor dimensions, shaft and bearings to handle a variety of applications at a specific horsepower rating. Since the power element is fixed, capacities can be pre-determined based on limestone and various reduction ratios.

Read More

Hammer Crusher Rotor > Crusher Parts > Products > DSMAC

2024.4.22 As for the weak part by stress analysis nephogram of rotor, we take the way of reinforcement and use the high-strength steel, and also the protective design with armour-style, which can increase 50%-100% the service of rotor. Use the design of adjustable hammer crusher rotor inertia, the rotor can greatly improve the crushing

Read More

Secondary Impact Crusher HSI - HAZEMAG

The rotor is the ‘heart’ of a secondary impact crusher, and the strength of this key component is tested relentlessly by the crushing process. Throughout HAZEMAG’s experience of over 70 years of in the industry, special emphasis has always been placed on rotor design, development, and the field of application.

Read More

Crushers – LT Construction Mining Machinery

LT Reversible Impactors are proven equipment for secondary and tertiary crushing applications. The Reversible Impactors are improved versions of hammer crushers. The hammer size impact blocks designs are made

Read More

PC Hammer Crusher

2024.5.8 Working Principle of PC Hammer Crusher: PC Hammer crusher mainly consists of frame, rotor, support iron and grate bars. The frame is divided into two parts: upper part and lower part which are welded by steel plates after being cut. ... Specifications. Model: PC400x300: PC600x400: PC800x600: Rotor diameter /mm: 400: 600: 800: Rotor

Read More

Products - HAZEMAG

HAZEMAG Primary Impact Crusher, Rock Crusher, Mineral Sizer, Hammermills, Apron Feeders, Conveyors, crushing plants, recycling plants, etc. ... The Rotor. Rotor Types; HAZEMAG 1214 Loan Rotor; Service. Service on Site; Repairs; ... HAZEMAG’s double-shaft hammer crushers, with efficient 3-stage crushing operations, are mainly used in the ...

Read More

titan® Crusher thyssenkrupp Polysius Crushing Technologies

titan® Double-Shaft Hammer Crusher. The titan® Double-Shaft Hammer Crusher is used for crushing medium-hard rock. For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials. It permits a large feed size and is capable of producing a clearly defined finished product size being preselected by the gaps of the discharge grate and ...

Read More

Horizontal Shaft Impactors - Astec

6 天之前 With three- or four-bar configurations, large feed opening and high-performance MPR rotor, Astec impact crushers are well-suited for a variety of applications. With 30% more uptime and 25% more production than competitive models, our HSIs deliver exceptional performance. ... HSI-Crusher-4250-Spec-Sheet-English Download (pdf) 390

Read More

Hammermill Impactors Eagle Crusher

Eagle Crusher Hammermills deliver maximum strength at a minimum weight and are ideal when budget and space are limited or when portable mounting is necessary. ... Eliminates rotor shifting during operation via special steel locking nut and locking washer on rotor shaft. ... Diameter of Hammer Swing: 24″ / 610mm: 24″ / 610mm: Width Between ...

Read More

Construction Working and Maintenance of Crushers for

2018.12.26 Operating the crusher with a completely filled crushing chamber. Choking Stoppage of the flow of material through the crusher, which is usually due to the wet and sticky material clogging exit points. Circulating Load The amount of oversize material returned back to the crusher from a screen in a closed circuit crushing system.

Read More

IMPACT CRUSHERS - HAZEMAG

Our single and double-rotor impactors process large feed sizes at high throughput rates at optimum degrees of crushing efficiency. A continuous equipment development programme ensures minimum wear, maximum availability, very low maintenance requirements and extreme flexibility regarding establishment of machine and product parameters.

Read More

Hammer Crusher - m.xinhaiepc

Hammer crusher is a kind of equipment with high production capacity, large reduction ratio and high crushing efficiency ... Variable hammer crusher specification. 【Product Structure】 Hammer Crusher. Click Image to Zoom. Hammer Crusher is composed of rack, rotor, sieve bar, hammer, etc. Motor drives rotor through transmission belt, and ...

Read More

CRUSHES PERFECT PRODUCT SQUEEZES YOUR COSTS

2023.9.14 crusher base. Add an off-the-shelf hydraulic hand pump and tank for double acting hydraulic cylinder or buy the electrically operated hydraulic rotor throttle system. “We increased sand production by 17–20% and decreased cost per ton by over 50%.” Sand producer, Chile. Replaced a 840 STD Barmac rotor from Metso with a 85HP

Read More

- مناجم الذهب على كشف الديدان من الجحيم

- مصفاة الذهب في مايوركا

- آلة كسارة الحجر الهيدروليكية أثر

- طاحونة الأنابيب للبيع

- آسیاب نورد در آسیاب سنگ شکن آفریقای جنوبی

- آلة تسحق الزجاج الأمامي

- الفك محطم الابتدائي الانحراف

- كسارات للبيع ما بعد الولادة

- صالح الكوارتز مصنع لتجهيز

- سعر كسارة الفك في ماليزيا

- سنگ زنی ماشین آلات در تولید

- شیشه و ماشین آلات تراش از آفریقای جنوبی

- استفاده از سنگ شکن رول سه گانه

- ماشین آلات پردازش گارنت شن و ماسه رودخانه

- سحق وطحن الفحم